Key Information

- Feeds high volumes of powder at a controlled rate.

- cGMP design

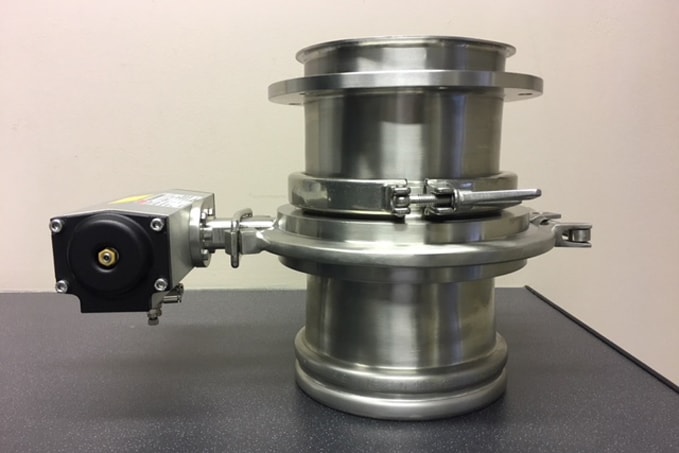

- Easy to install – upper and lower half connections can be supplied to match those already at the customers site. The valve works off a pneumatic actuator requiring a connection to compressed air, meaning no wiring up and making the valve easier for validation in ATEX zones.

- All parts can be easily dismantled for ease of cleaning and replacing of wearing parts.

- All contact parts are 316L and non-metallic parts are FDA compliant. Full documentation is provided with each valve.

- Can be supplied with small gap between rotor and gasket to prevent rubbing of gasket with each revolution. This prevents ingress of gasket into product and enhances the life-span of the gasket.

Technical Description

It is designed for applications where large volumes of powder are required, but at a controlled pace. The valve works using a pneumatic actuator rotating at 180° dosing several pockets of material with each rotation.

This gives the customer greater control and understanding of the amount of powder dosed with each turn, giving repeatable and consistent results.

The light-duty rotary valve will commonly be found feeding hoppers, packing lines and tablet presses.

Materials

> Body and rotor: Stainless steel EN 1.4404 (AISI 316L)

> Seals: Translucent Silicone, EPDM, FKM (Viton®), PTFE

Motion Drive

> Pneumatic actuator

Finish

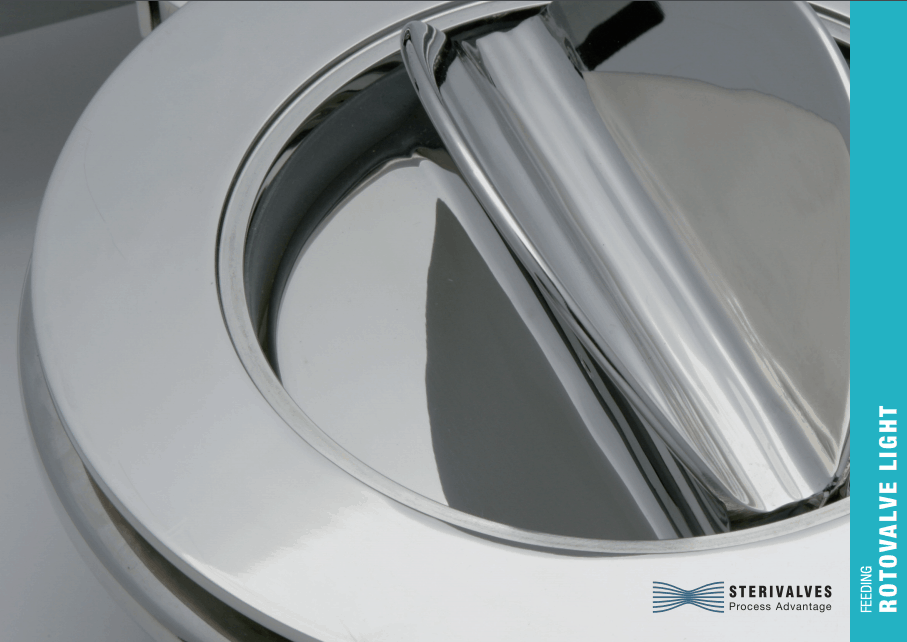

> Ra 0.5 μm internal

> Ra 1.2 μm external

Declarations and Certifications

> FDA Certification (CFR § 177.2600)

> Material Certificate 3.1 as per EN10204

> ATEX

Sizes

DN 80, DN 100, DN 150, DN 200, DN 250, DN 300, DN 350, DN 400