Key Information

- Delivers the user high accuracy dosing and complete control over feeding of material.

- cGMP design

- Easy to install – upper and lower half connections can be supplied to match those already at the customers site.

- All parts can be easily dismantled for ease of cleaning and replacing of wearing parts.

- All contact parts are 316L and non-metallic parts are FDA compliant. Full documentation is provided with each valve

Technical Description

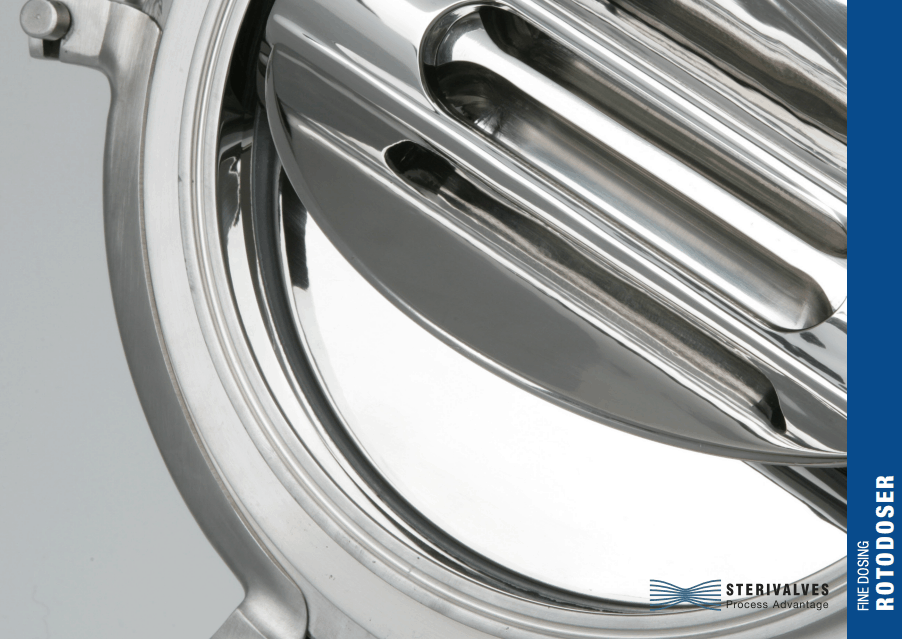

Working off two internal rotors which are independently operated by motor and pneumatic actuator, the Rotodoser allows the user to hit an accuracy up to ± 10 grams (depending on product characteristics).

Customers set a ‘target weight’ on the Rotodoser HMI controls which are connected to weigh scales. If the target weight is 25kgs, then the vane operated by the pneumatic actuator will perform the bulk dosing part, bringing it to 24kgs.

Using two rotors allows the user to reach a target weight quickly, where just the small interior rotor would take far longer. Once the valve has dosed to 24kgs, the smaller interior rotor will take over and bring the user to their target weight.

Materials

> Body: Main rotor and secondary: Stainless steel EN 1.4404 (AISI 316L)

> Seals: Translucent Silicone, EPDM, FKM (Viton®)

Motion Drive

> Pneumatic actuator (main rotor)

> Pneumatic or electric motor (secondary rotor)

> Pneumatic actuator (secondary rotor)

Finish

> Ra 0.5 μm internal

> Ra 1.2 μm external

Declarations and Certifications

> FDA Certification (CFR § 177.2600),

> Material Certificate 3.1 as per EN10204

> ATEX

Sizes

DN 100, DN 150, DN 200, DN 250, DN 300