Key Information

Hanningfield is able to supply stainless steel Intermediate Bulk Containers (IBCs) for use in the pharmaceutical, food and allied industries.

- Safe and contained method for storing and transporting powder

- Highly flexible, with various methods for dust-tight charging and discharging

Features & Benefits

Stainless Steel Construction

316L contact parts and FDA compliant seals

Various Sizes

Various capacities and shapes available

Custom Designs

Custom design available (and ability to replicate existing design)

Technical Description

Design

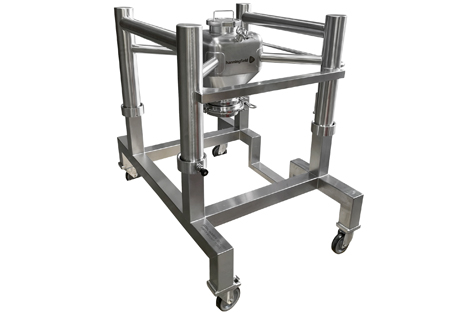

Intermediate Bulk Containers (IBCs) for use in the pharmaceutical, food and allied industries. The containers are designed for the safe and contained transport, storage and handling of material. Typically the IBCs are supplied with capacity of 150 – 2000 litres, but can be custom made to suit any process requirement or application.

Customise Your IBC

The IBCs can be executed in various designs, including castors for mobility, corner stacking profile and lifting loops for handling via forklift or post hoist.

Construction

As standard, all contact parts are manufactured from 316L stainless steel (1.4404), with FDA compliant seals, gaskets etc. Non-contact parts such as the frame and legs are manufactured from 304 stainless steel (1.4301). All standard materials of construction and surface finishes can be upgraded or downgraded upon request.