Key Information

The Hanningfield Lump Breaker is designed for the simple deagglomeration of compacted material into smaller particles. Lump breakers can process up to 10,000 kgs/hr (depending on application specifics) and are capable of particle size reduction down to 10mm.

- High throughput solution for breaking agglomerated material

- Perfect for pre-milling by reducing particle to manageable size

- Can be mounted in-line for feeding downstream process (gravity feed or vacuum transfer)

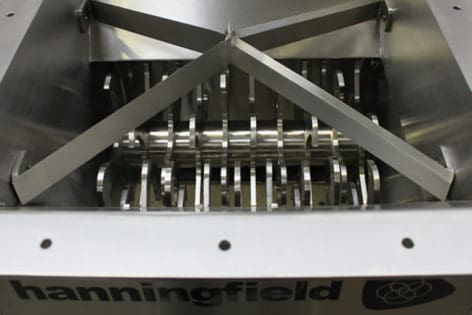

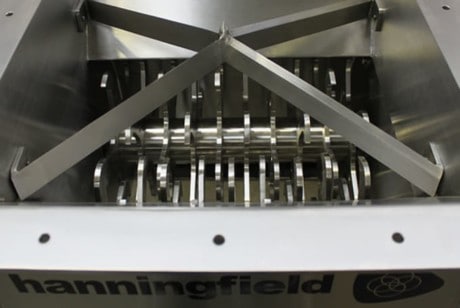

- Breaker bars can be removed for easy clean

Features & Benefits

Stainless Steel Construction

316L contact parts with FDA compliant seals

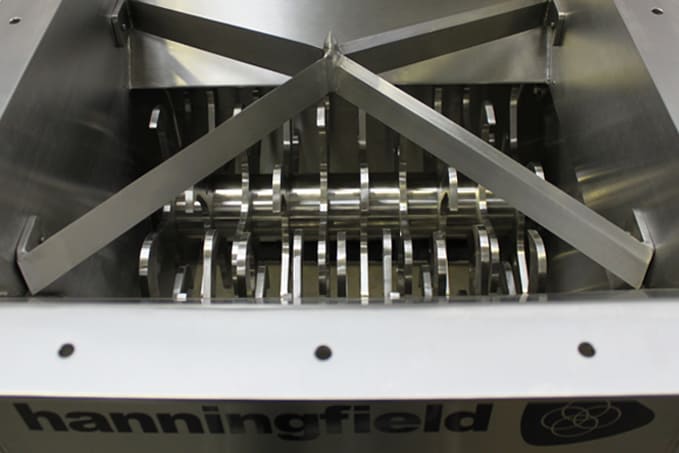

Sizing Grid (optional)

Optional sizing grid for achieving

smaller particles

ATEX / Ex-proof

ATEX (ex-proof) versions available

Technical Description

Why Use a Lump Breaker?

Deagglomeration is typically required for any material which has compacted during storage or transportation and requires reviving prior to processing. The deagglomeration of bulk material vastly improves its flow-ability and is vital to the success of downstream processes such as milling, sieving, mixing, bagging and conveying.

Design & Operation

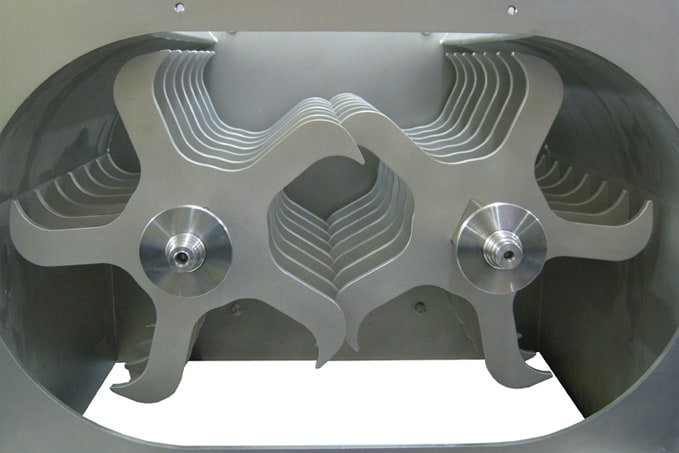

The heavy duty design is available in dual-shaft execution. The cross meshed rotating breaker arms perform size reduction by cutting and shearing the material. The distance between blades can be adjusted according to the required particle size and are easily removed for maintenance or replacement.

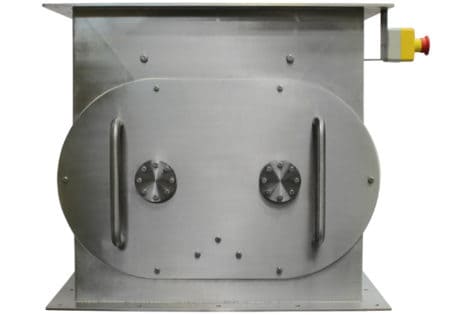

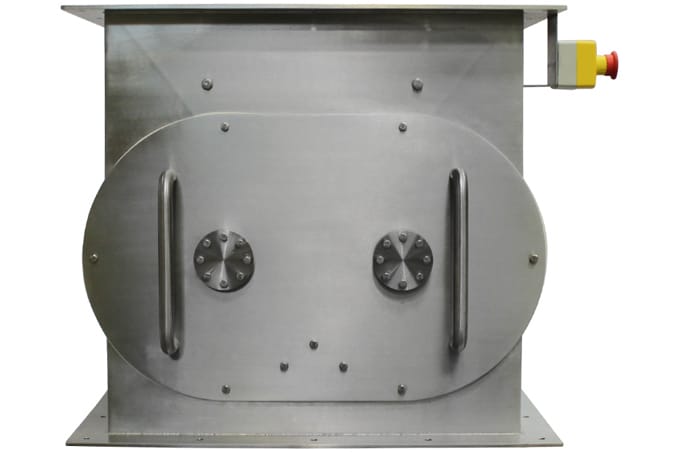

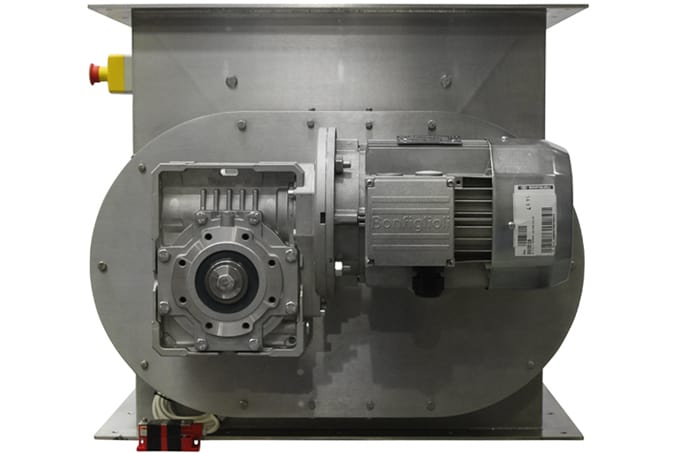

The unit features a 2.2kW motor, set to a speed of 200RPM (variable speed available), with 450mm x 558mm inlet and outlet connections (rectangular flange with bolt holes).

Construction

As standard, all contact parts are manufactured from 316L stainless steel (180 grit), with FDA compliant seals, gaskets etc. Non-contact parts such as frames, motor covers and control panels are manufactured from 304 stainless steel (150 grit). All standard materials of construction and surface finishes can be upgraded or downgraded upon request.

Customise Your Lump Breaker

Various mounting solutions (e.g. mobile frame) are available and the lump breaker can be customised with a selection of inlet and outlet configurations including hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors or any other bespoke design required for process integration.

Lump breakers can also be modified with optional upgrade features including variable speed and ATEX execution where applicable. All equipment can be supplied with full validation documentation (FS/DS, FAT, SAT, IQ/OQ) and 3.1 mill certificates to EN10204.