Key Information

- Cost efficiencies (using one machine for sifting and milling)

- High throughput for maximum productivity

- Inline feed and discharge for higher capacity and ease of system integration

- Achieve various particle sizes on one machine (by changing the sifter basket / mill screen)

- Easy to operate

- Low heat, dust and noise generation for improved working environment

- Process scalability from lab to pilot to production

Features & Benefits

Stainless Steel Construction

316L contact parts

FDA Compliant

All seals FDA compliant (silicone, PTFE etc.)

Various Mesh Sizes

Enabling multi-product usage (both sifter basket and mill screen)

Easy-Clean GMP Design

Detachable mill and sifter heads for CIP/WIP

ATEX / Ex-proof

ATEX (ex-proof) versions available

Technical Description

Design & Operation

Many powder processes involve both sifting and milling – a sifter for powder screening and/or to de-lump agglomerated material, and a mill for final particle sizing. A cost-effective way of achieving this is to use a machine with interchangeable sifter and mill heads.

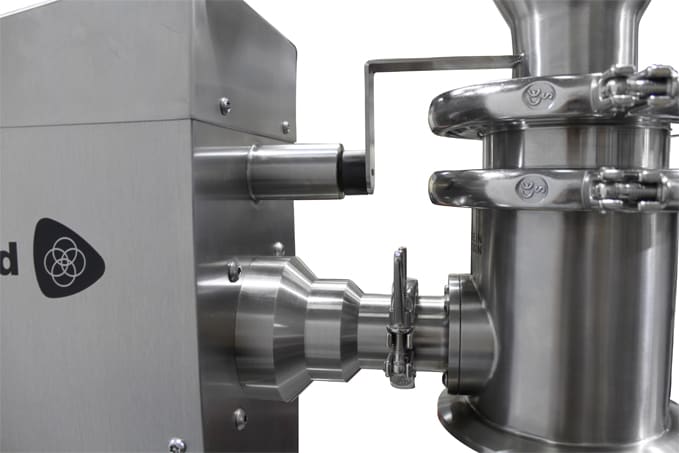

The Particle Sizing Solution (PSS) is fitted with a coupling drive arm so the heads can be swapped depending on your needs. See how simply and quickly the machine heads can be swapped over in our videos below.

Conical Mill

The Uni-Mill uses conical milling technology to achieve the narrowest possible PSD, offering a reliable and high performance solution to customers.

All models provide excellent versatility as they come with customisable and interchangeable tooling, allowing operators to change the screen hole size, screen hole shape and impeller type. It is therefore possible to use the same mill for multiple products and various applications, including dry and wet milling.

Centrifugal Sifter

The Kwik-Sift is designed for fast and effective powder screening, helping guarantee material integrity through the capture of alien objects (such as nuts, bolts, washers, cable ties). Compared to traditional sieving, the Kwik-Sift achieves security screening at a much higher throughput.

It can also be used for the simple de-lumping of agglomerated material by incorporating a single or dual spoiler arm onto the chute via a tri-clover.