Key Information

- High throughput for maximum productivity

- Inline feed and discharge for higher capacity and ease of system integration

- Achieve various particle sizes on one machine, simply by changing screen and/or impeller

- Various screens available to meet the demands of many different applications and processes

- Spacerless design with preset optimised ‘gap’ for milling

- Easy to operate

- Low heat, dust and noise generation for improved working environment

- Process scalability from lab to pilot to production

Features & Benefits

Stainless Steel Construction

316L contact parts

FDA Compliant

All seals FDA compliant (silicone, PTFE etc.)

No Metal-to-Metal Contact

Designed with an optimal, spacer-less gap (to avoid metal-to-metal contact)

Easy-Clean GMP Design

Optional features include detachable millhead for autoclave or CIP/WIP

ATEX / Ex-proof

ATEX (ex-proof) versions available

Technical Description

Design & Operation

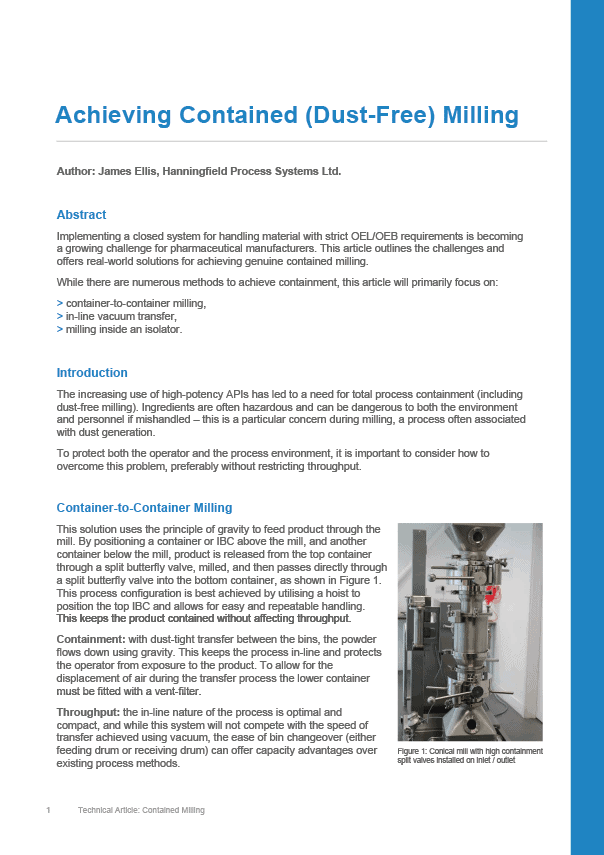

The Hanningfield Uni-Mill U-Series (M05-U, M10-U, M20-U, M30-U) utilises the current industry standard under-driven conical mill design, featuring an IP6X gearbox-driven impeller, rotating inside a screen (60º inclusive screen angle). This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

The Uni-Mill under-driven models are designed with an optimal, spacer-less gap (to avoid metal-to-metal contact); this offers a major benefit compared with over-driven conical mills where the distance between the screen and impeller has to be set manually using spacers (gap setting). This makes tooling changes on under-driven conical mills faster and easier by guaranteeing the closest possible gap every time. Other benefits of the Uni-Mill under-driven are the in-line inlet and outlet offering higher throughput, a more compact design and improved sanitary construction.

Size Reduction

All Hanningfield mills are available with a wide range of screen and impeller tooling, helping to achieve the various required final particle sizes and throughputs. Conical mills are typically suitable for size reduction down to approximately 150 microns (80 mesh) with minimal heat generation and are suitable for both dry and wet milling applications.

Construction

As standard, all contact parts are manufactured from 316L stainless steel (180 grit), with FDA compliant seals, gaskets etc. Non-contact parts such as frames, motor covers and control panels are manufactured from 304 stainless steel (150 grit). All standard materials of construction and surface finishes can be upgraded or downgraded upon request.

Customise Your Mill

Various mounting solutions are available (mobile frame, swing-arm, fixed post, hoist mounted etc.) and the mill can be customised with a selection of inlet and outlet configurations including hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors or any other bespoke design required for process integration.

The design can be modified to include optional upgrade features including autoclave adaptor kit (detachable mill-head for sterilisation), temperature monitoring, CIP, WIP, pre-breakers, nitrogen purging and ATEX execution where applicable. All equipment can be supplied with full validation documentation (FS/DS, FAT, SAT, IQ/OQ) and 3.1 mill certificates to EN10204.