Key Information

- Eliminates manual handling

- Ensures filling machine never ‘runs dry’

- Gentle convey with virtually zero capsule damage

- Suitable for all sizes of hard shell capsule

Features & Benefits

Stainless Steel

316L contact parts with FDA compliant seals

FDA Compliant

All seals FDA compliant (silicone, PTFE etc.)

Level Control (optional)

Optional level control in filling machine hopper to automate loading process

Low Noise

Very low noise levels for a better working environment

Customisable Hopper

Hopper can be customised to accommodate extra capsules

Technical Description

Design & Operation

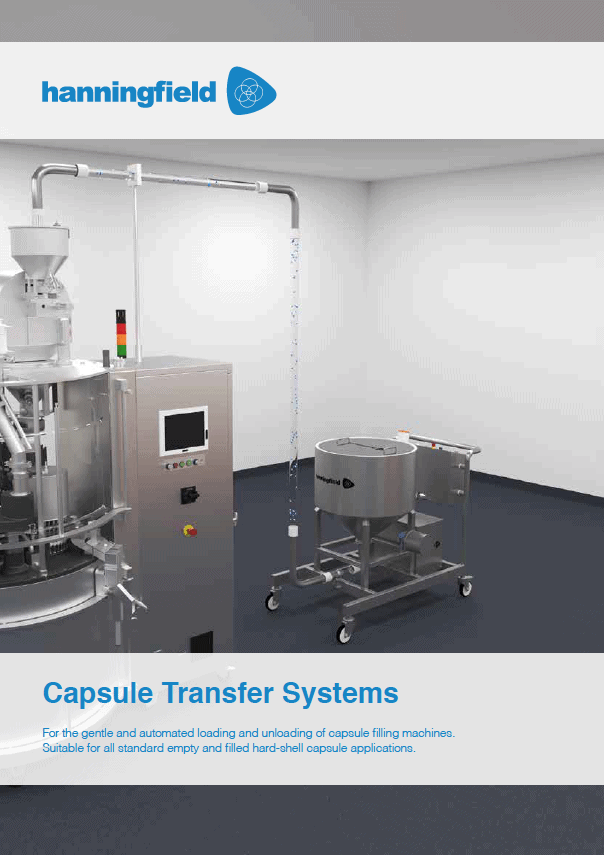

Designed to overcome the problems of conventional mechanical systems, the CapsuJet is ideal for the automatic loading and unloading of capsule filling machines.

The CapsuJet C20 capsule transfer system is designed for the loading of empty capsules from ground level into the capsule filling machine. The C20 is capable of loading up to 300,000 capsules per hour.

The CapsuJet FCC capsule transfer system is designed for the unloading of capsule filling machines, transferring filled capsules to a downstream container or process. The FCC can transfer up to 200,000 capsules per hour.

Construction

As standard, both capsule transfer system models are constructed with all contact parts manufactured from 316L stainless steel (180 grit), with FDA compliant seals, gaskets etc. Non-contact parts such as frames, motor covers and control panels are manufactured from 304 stainless steel (150 grit). All standard materials of construction and surface finishes can be upgraded or downgraded upon request.

Documentation

All equipment can be fully customised to satisfy specific application requirements and can be supplied with full validation documents (FS/DS, FAT, SAT, IQ/OQ) and mill certificates to EN10204 (3.1).