Key Information

- High efficiency design capturing 90 – 99.9%

- Prevents blinding and replacement of expensive filters in central dust extraction system or vacuum cleaner

- Improved batch reconciliation and yields

- Almost zero maintenance costs with no moving parts or filters

- Recovered powder can be reintroduced – minimising material loss and saving money

Features & Benefits

Stainless Steel Construction

316L contact parts with FDA compliant seals

Optional Manifold

For collecting waste powder from deduster or polishing machine

Easy Clean

Assembled using Tri-Clamps for fast and easy dismantling for cleaning

Technical Description

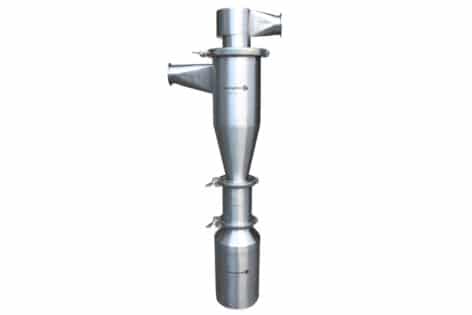

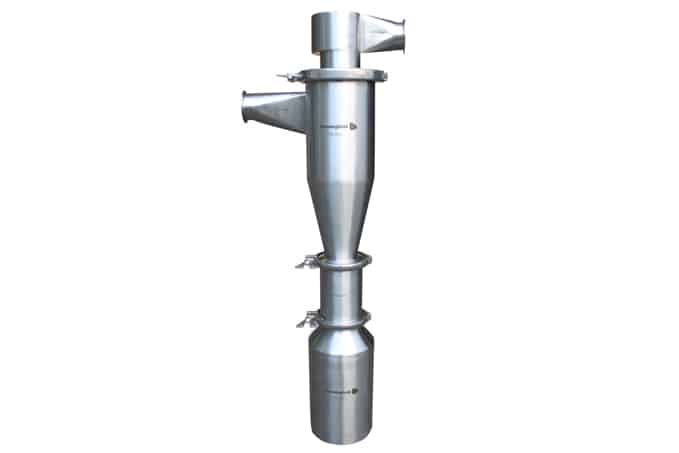

Design & Operation

The Hanningfield Uni-Dust cyclone is specifically designed for the recovery of waste powder from pharmaceutical OSD processes such as compression and encapsulation, typically capturing between 90 – 99.9% of waste powder. We have successfully installed our cyclone to Fette, Manesty, Korsch, Zanasi, Bosch, Kilian and numerous other process machines. Where required, the cyclone can incorporate a manifold for connection to ancillary equipment such as tablet dedusters or capsule polishers.

The Uni-Dust cyclone is proven to be equally effective in numerous other applications including sachet filling, spray drying, inhalation and any other process where excess dust is extracted. The captured waste material can be used for batch loss reconciliation, or even reintroduced to the process (where protocol permits).

The cyclone connects to the process machinery via flexible hose or stainless steel pipework (multiple lines can be accommodated using a manifold). Inside the cyclone, vortex separation causes the solid particles to hit the outside wall of the cyclone and fall to the catchpot at the base of the cyclone. This allows ‘clean’ air to pass downstream (to the dust extraction source) and prevents a build-up of material in the filters, which can be time consuming and expensive to replace. For additional security, a HEPA filter can be integrated after the cyclone and before the vacuum source. The cyclone can be retrofitted to your existing dust extraction line, or can be supplied with a side channel blower to provide a dedicated vacuum source.

Construction

The filterless Uni-Dust series of powder recovery cyclones (Type 5, Type 10, Type 20, Type 30, Type 40, Type 50, Type 60) features a crevice-free, GMP stainless steel construction, enabling the unit to be mounted inside the process room (the cyclone can be supplied on a portable trolley, wall-bracket, floor pedestal or free-standing). The Uni-Dust is assembled using Tri-Clamps for fast and easy dismantling for cleaning and has no moving parts – therefore generating no mechanical noise. All models of Uni-Dust cyclone are suitable for use in Zone 0/20 ATEX environments both internally and externally.

Customise Your Cyclone

For greater control over your process, the Uni-Dust cyclone can be modified to include various optional upgrade features including safe-change, level control or sight glass (in catchpot), isolation valve and air balancing valves.

Documentation

All equipment can be supplied with full validation documentation (FS/DS, FAT, SAT, IQ/OQ) and 3.1 mill certificates to EN10204.