Features & Benefits

Stainless Steel Construction

316L contact parts and FDA compliant seals

Various Sizes

Various capacities and shapes available

Custom Designs

Custom design available (and ability to replicate existing design)

Technical Description

Design

For the gentle handling of tablets, Hanningfield offer a specifically designed IBC. The design uses a shallow body angle and a flexible-vane outlet valve to minimise risk of tablet breakage and damage. The IBC can be supplied with an outlet chute for transferring the tablets into a coater.

Customise Your Tablet IBC

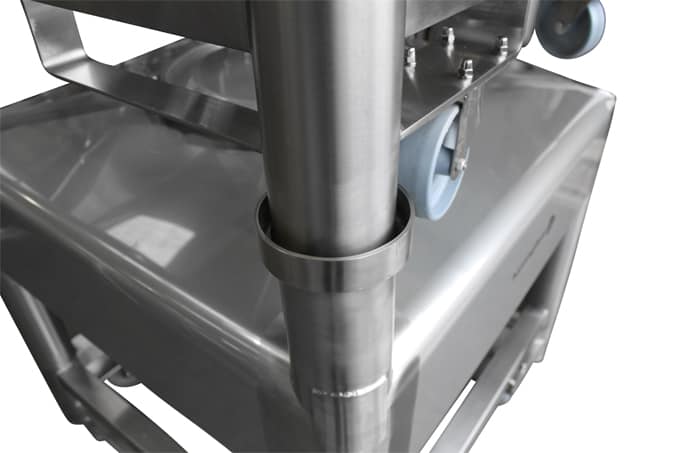

The containers can be executed in various designs, including castors for mobility, corner stacking profile and lifting loops for handling via forklift or post hoist. The containers are also suitable for validatable cleaning using a wash booth or wash station.

Construction

Hanningfield’s Tablet IBCs are suitable for use in the pharmaceutical, food and allied industries. As standard, all contact parts are manufactured from 316L stainless steel (1.4404), with FDA compliant seals, gaskets etc. Non-contact parts such as the frame and legs are manufactured from 304 stainless steel (1.4301). All standard materials of construction and surface finishes can be upgraded or downgraded upon request.