Key Information

- Stops flow of powder, allowing for discharge when required. Ideal for use on IBCs and containers.

- cGMP design

- Easy to install – upper and lower half connections can be supplied to match those already at the customers site.

- All parts can be easily dismantled for ease of cleaning and replacing of wearing parts.

- All contact parts are 316L and non-metallic parts are FDA compliant. Full documentation is provided with each valve.

- Can be supplied with an actuator to automate the discharge where a manual lever is not suitable.

- The butterfly valve can be fitted with various additions to improve its working performance, such as a positioner when the customer wants to control the angle of the butterfly vane or pneumatic vibrator to encourage cohesive materials with poor flowability.

Technical Description

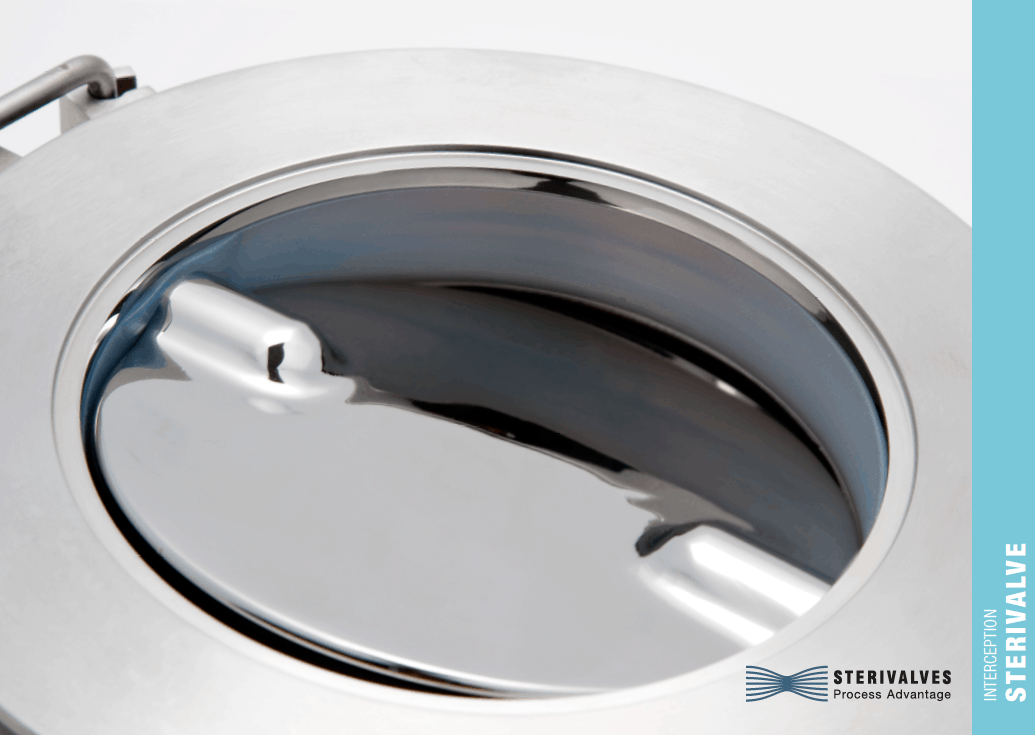

Butterfly valves offer the user no real control over the powder flow and will most commonly be found on the inlet and outlet of containers, and on hoppers and pipes. The simple design and working principle allows the user to contain material, and then discharge when required.

Materials of Construction

> Body and Butterfly: Stainless steel EN 1.4404 (AISI 316L)

> Seals: Translucent Silicone, EPDM, FKM (Viton®), PTFE

Motion Drive

> Handle

> Pneumatic actuator

Finish

> Ra 0.5 μm internal

> Ra 1.2 μm external

Declarations and Certifications

> FDA Certification (CFR § 177.2600),

> Material Certificate 3.1 as per EN10204,

> ATEX

Sizes

DN 80, DN 100, DN 150, DN 200, DN 250, DN 300, DN 350, DN 400