Hygienic Valves are crucial in controlling the flow and containment of material between equipment before discharge. A important decision to ensure the proper functioning of your process and smooth delivery of your material is to select the correct valve. This can ensure that your system runs at optimum capacity, whilst saving time and money on potential lost material.

At Hanningfield, we offer our customers a wide range of standard and non-standard Hygienic Valve options to suit your specific application. Your process does not have to fit into a standard Butterfly Valve or Ball Valve category – there are many different types of valve available which could better suit your application.

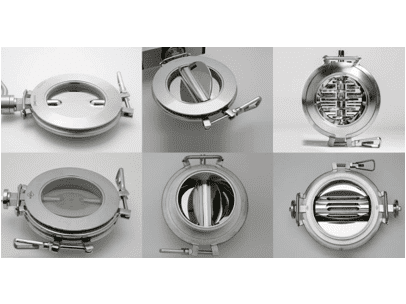

The Sterivalves range of stainless steel modular hygienic process valves offers the perfect solution for the control of powders and liquids in the pharmaceutical and associated industries. Most hygienic valves can be manufactured to meet special applications and come with an extensive range of accessories including actuators, position sensors, mounting flanges and control systems.

One of the major advantages of the Sterivalve system is the compact design that offers a very slim profile to the main body. Modular construction and interchangeable parts helps keep the spares requirements to a minimum.

Our range of valves includes:

> Sterivalve – Hygienic Butterfly Valves

> Sterisplit – Split Butterfly Valves

> Flexivalve – Flexible Vane Valves

> Rotovalve (Light) – Light Duty Rotary Valves

We can supply all spare and wearing parts related to the Sterivalves range, including technical documentation.

Choose your Application

Select your application from the list below and we’ll take you to the valve you need:

> Flow Interception (Sanitary Butterfly Valve)

> Flow Interception (Flexible Butterfly Valve)

> Feeding

> Dosing

Get in Touch

If you would like to speak to one of our experts regarding our range of valves or you would like a quote for one of our products, send us a message using our Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.