The prevalence of APIs in pharmaceutical manufacturing has resulted in the apparent and ever-increasing need for ‘containment.’ However, defining the relevant level of required containment and creating a real-world solution can be slightly more complex. Many pharmaceutical processes involve the manipulation or transfer of powder, which can generate dust.

Containment itself adds expense and even well-designed systems are cumbersome and time-consuming. Hence, understanding the hazards presented by a particular material is essential to shaping the chosen method of containment and ensuring health and safety compliance without creating unnecessary impediments to process efficiency.

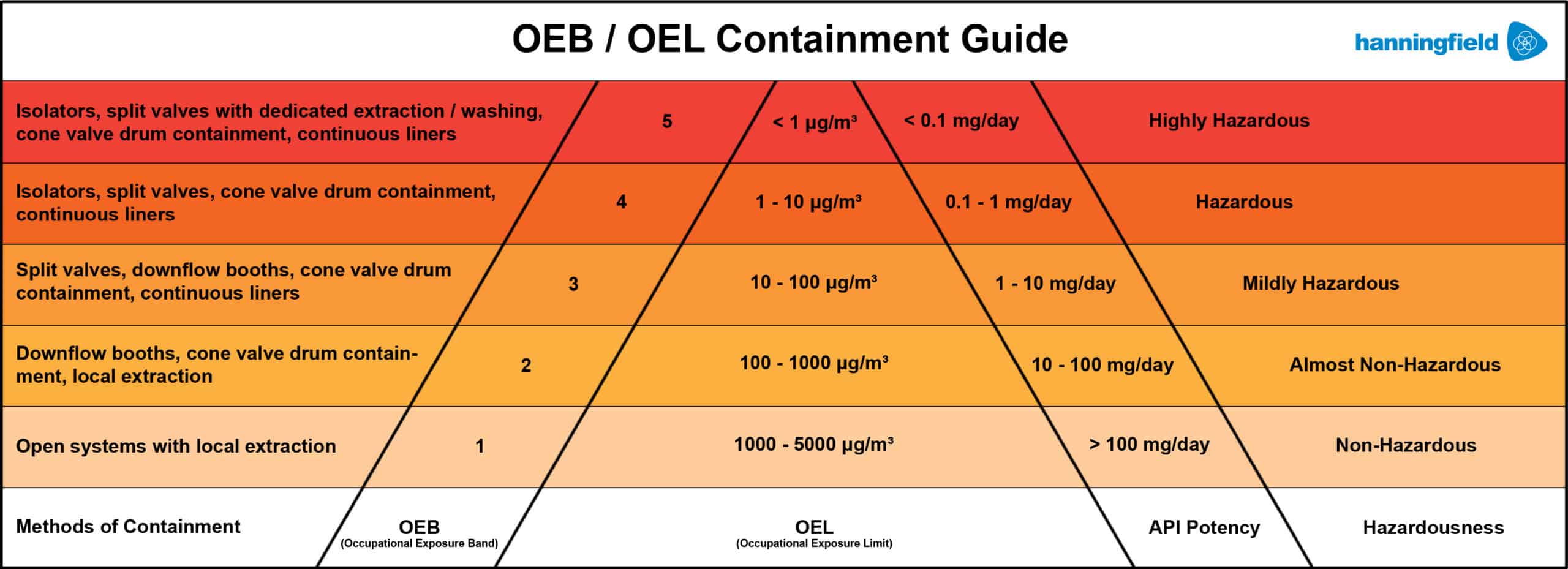

For each powder handled, the Material Safety Data Sheets (MSDS) should specify the recommended Occupational Exposure Band (OEB), or at the very least should specify the Threshold Limit Values (TLV), usually indicated as mg/m3 or PPM (parts per million). These values can be cross-referenced with the below chart to ensure the appropriate engineering controls are implemented alongside existing site standards for GMP and PPE.

However, simply identifying the correct OEB means little without understanding the available containment options for each band.

OEB Level 1

This is the lowest OEB level, where the toxicity of the material will not present a hazard to the operator. Consequently, containment may be limited to simple local extraction or ventilation. For example, opening a drum in a well ventilated process room should provide a suitable working environment.

OEB Level 2

At this OEB level there is a minor risk from the toxicity of the material. Pragmatic steps should be taken to prevent uncontrolled operator exposure. For example, in addition to previous containment methods, drums should be opened within a downflow / crossflow booth or with dedicated local exhaust ventilation. Alternatively the drums can be fitted with cone valves for enabling dust-tight transfer.

OEB Level 3

At this OEB level, the material is mildly hazardous, hence measures should be taken to prevent operator exposure. Flexible isolators and glove bags are frequently used to provide a simple barrier, whilst continuous liner systems can also provide a suitable method of contained discharge. Material transfer is commonly performed using Split Butterfly Valves.

OEB Level 4

At this OEB level, the material is hazardous, hence significant measures should be taken to prevent operator exposure. There should be a physical barrier between the operator and the material. Isolators and Restricted-Access Barrier Systems (RABS) are common, whereby material can be openly handled inside the dedicated enclosure, with the operator manipulating the equipment and material externally through glove ports.

OEB Level 5

At this OEB level, the material is highly hazardous, hence significant measures should be taken to prevent operator exposure. There should be a permanent physical barrier between the operator and the material. Closed material handling and transfer should be undertaken inside Isolators and Restricted-Access Barrier Systems (RABS) via glove ports. Even inside the isolator, material should not be openly handled instead utilising RTPs and split valves for contained handling.

References and Further Reading

http://www.powderbulksolids.com/article/containment-system-concepts-oeb1-through-oeb5

http://www.pharmtech.com/outsourcing-formulation-development-high-potency-compounds