Introducing Hanningfield’s Brand New Uni-Vac Brochure

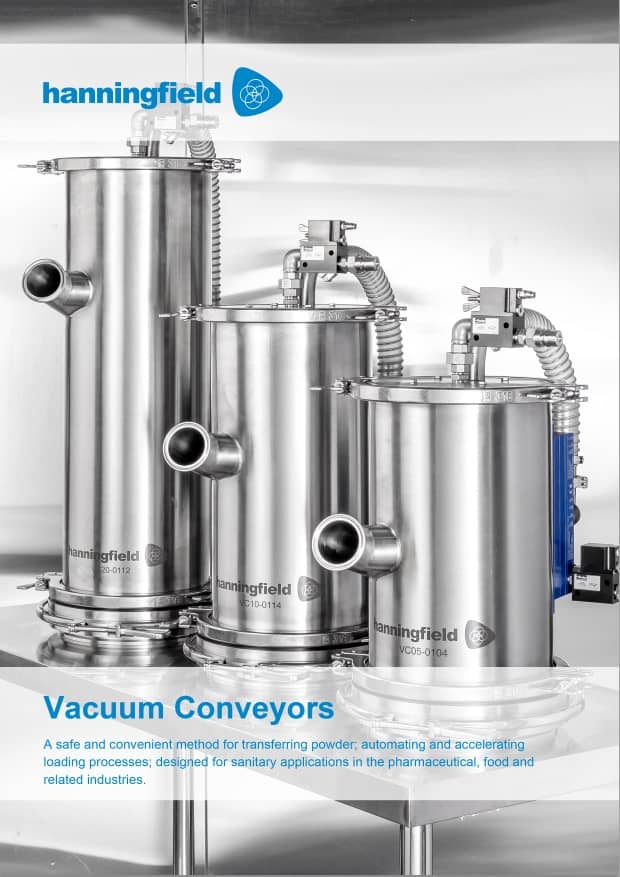

Make sure to download our brand new Uni-Vac brochure. Inside you will find information on the features and benefits of introducing a Hanningfield vacuum transfer system to your process. Find out about the Uni-Vac’s advantages and explore the different Uni-Vac models available. In addition, learn more about example applications and specialist applications of our vacuum transfer systems.

Process Applications

The Hanningfield Uni-Vac offers many solutions to improve your operation and save money. Below are just a few examples of how the Hanningfield Uni-Vac can be employed to improve your powder operations.

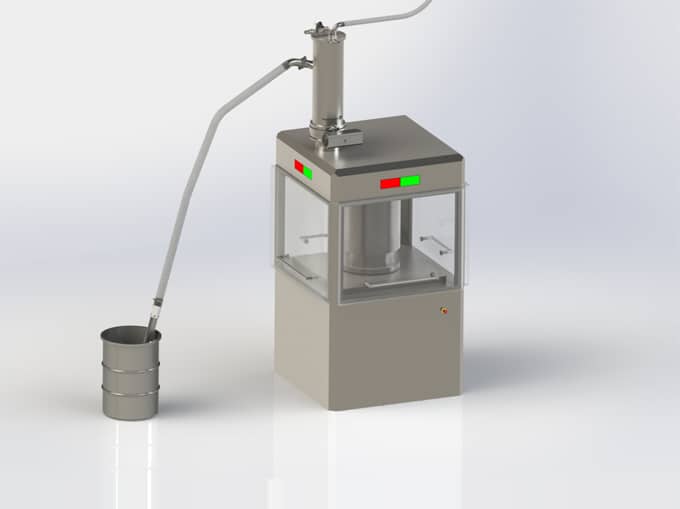

Vacuum Transfer from Drum to Process Machine

Finished powder can be sucked from the ground floor into the received hopper on the process machine. Once full, the outlet valve opens and discharges the material into the machine.

In-Line Vacuum Milling or Sieving

In-line vacuum conveying through a mill or sieve is a fast and efficient method of powder transfer. n-line vacuum also improves containment and significantly speeds up the conveying process.

Fill Vacuum Transfer into a Vessel

Another common application is conveying material from a drum or IBC at floor level up and into a mixing vessel. Containment, reduced waste and improved process times are all major benefits.

Vacuum Transfer into a High Shear Mixer

Powder can be conveyed from a drum of IBC located at floor level up to the mixer inlet. This system avoids manual handling and reduces process time.

Direct Loading (into a Blender)

Direct loading reduces the number of moving parts and improves efficiency by reducing conveying times, as the system operates via a continuous transfer (with no discharge or backwash sequence).

Material charges directly and continuously into the inlet port on the blender.

Get in Touch

If you would like to speak to one of our experts regarding our Vacuum Transfer Systems or you would like a quote for one of our products, send us a message using our Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.