Seal it. Cap it. Spigot it. Charge it.

Silicone dust caps provide the ideal solution to achieving dust-tight containment during processing. The Uni-Cap is hygienically moulded in one piece from FDA compliant pure silicone rubber. This offers a durable and easy-clean design. Hanningfield’s range of Uni-Caps have proven highly successful in providing many of our customers with an improved method for the transfer of powders, protecting both the operators and the process environment.

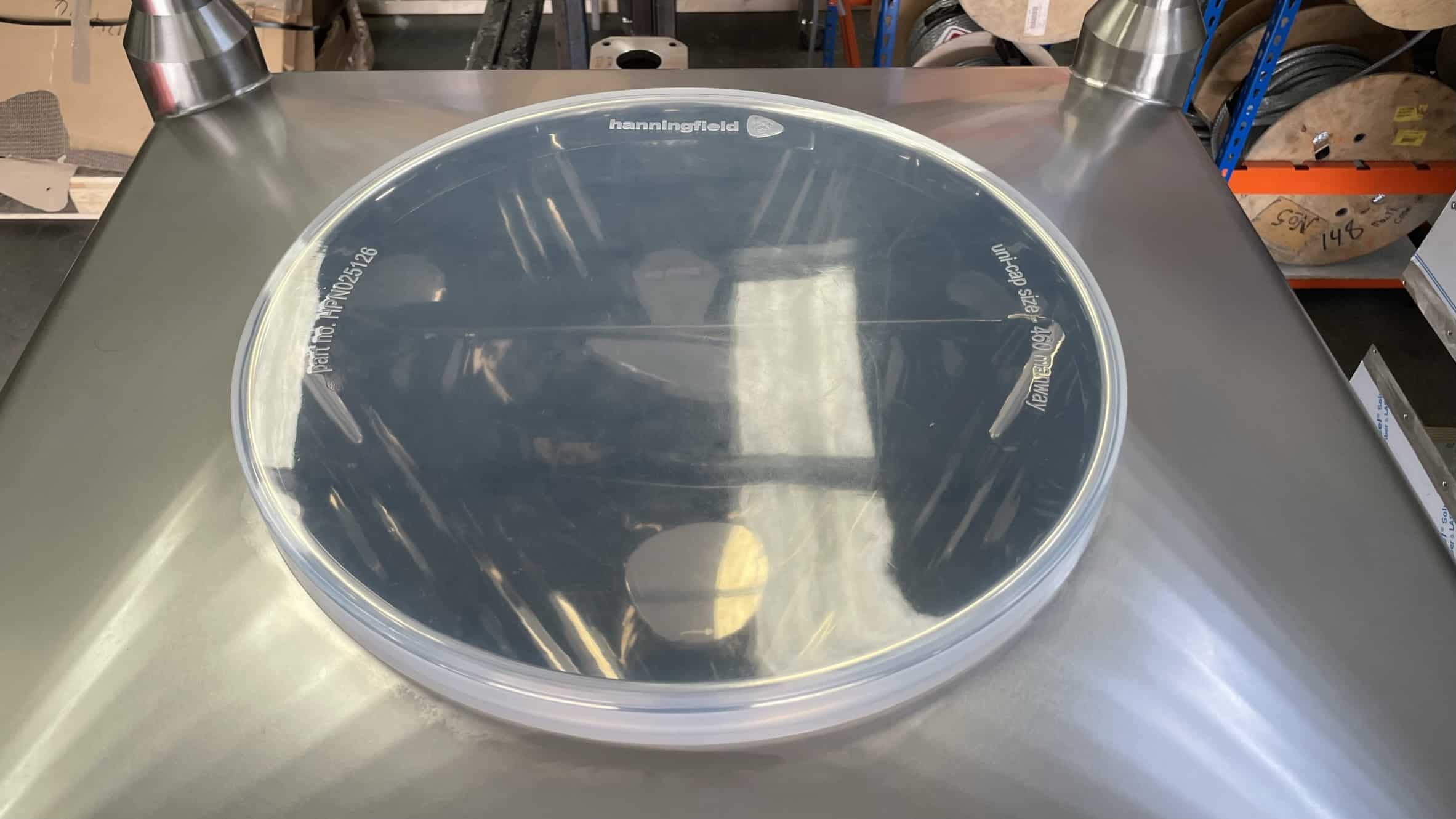

Recently, Hanningfield officially launched a brand new range of fully transparent dust caps. Take a closer look by watching the video below >>

The Uni-Cap+ range offers an enhanced design and excellent visibility combined with the stringent standards our customers have come to expect from Hanningfield products.

The platinum-cured silicone is compliant to FDA 177.2600 and is USP Class VI. The silicone is TSE/BSE free, ADI free and phthalates free. The range is made in the UK and the manufacture batch ID can be embossed onto the silicone cap for traceability.

The Uni-Cap+ is currently available in the following sizes:

- 150mm (to fit 6″ Tri-Clamp ferrule)

- 200mm (to fit 8” Tri-Clamp ferrule)

- 305mm (to fit typical 305mm IBC manway)

- 460mm (to fit typical 460mm IBC manway)

We also supply the stainless steel mounting rings in corresponding sizes to complement our new range of transparent silicone dust caps.

Our Uni-Cap and Uni-Cap+ models can be easily fitted or retro-fitted to any process. As with all our dust caps, cutting a hole in the centre creates a dust-tight seal can be made with the penetrating spigot. This enables the contained charging of mills, tablet presses, vessels, drums / IBCs etc.

Get in Touch

If you would like to speak to one of our experts regarding our Transparent Silicone Dust Caps or you would like a quote for one of our products, send us a message using our Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.