At Hanningfield, much of our product range can be used alongside other equipment and, therefore, has been built with system integration in mind. We understand that our equipment is typically installed in-line with a range of other process machines, so we ensure that our equipment integrates perfectly with your existing set-up during our design phase.

Not only are we able to supply our standard range of machinery, but we are also able to draw upon over 35 years of engineering and pharmaceutical expertise to deliver fill turnkey systems. By giving full care and attention to the interfaces, not just the ‘big-ticket’ items, Hanningfield is able to create functional systems for customers through a combination of custom built machinery.

Please find below some example system ideas showing how processes can be integrated together for greater efficiencies >>

System Integration: Typical Applications

Unloading a Fluid Bed Dryer

The Hanningfield Uni-Vac vacuum transfer system can be used to convey material from an FBD after the drying process is complete (shown here with an in-line mill for improved particle size distribution.

Vacuum Transfer from Drum to Process Machine

The conveyor sucks material from a ground floor drum, up into the Uni-Vac hopper. Once full, the outlet valve opens and discharges the material into the machine.

IBC to IBC Milling

By positioning a bin above the mill, and another bin below the mill, product is released from the top IBC, the product is then milled, and then passes directly into the bottom IBC.

In-Line Vacuum Milling

In-Line vacuum transfer through a conical mill helps to achieve automated, dust-tight milling. An over-driven conical mill is in the example shown, however the same process can be achieved with an under-driven conical mill.

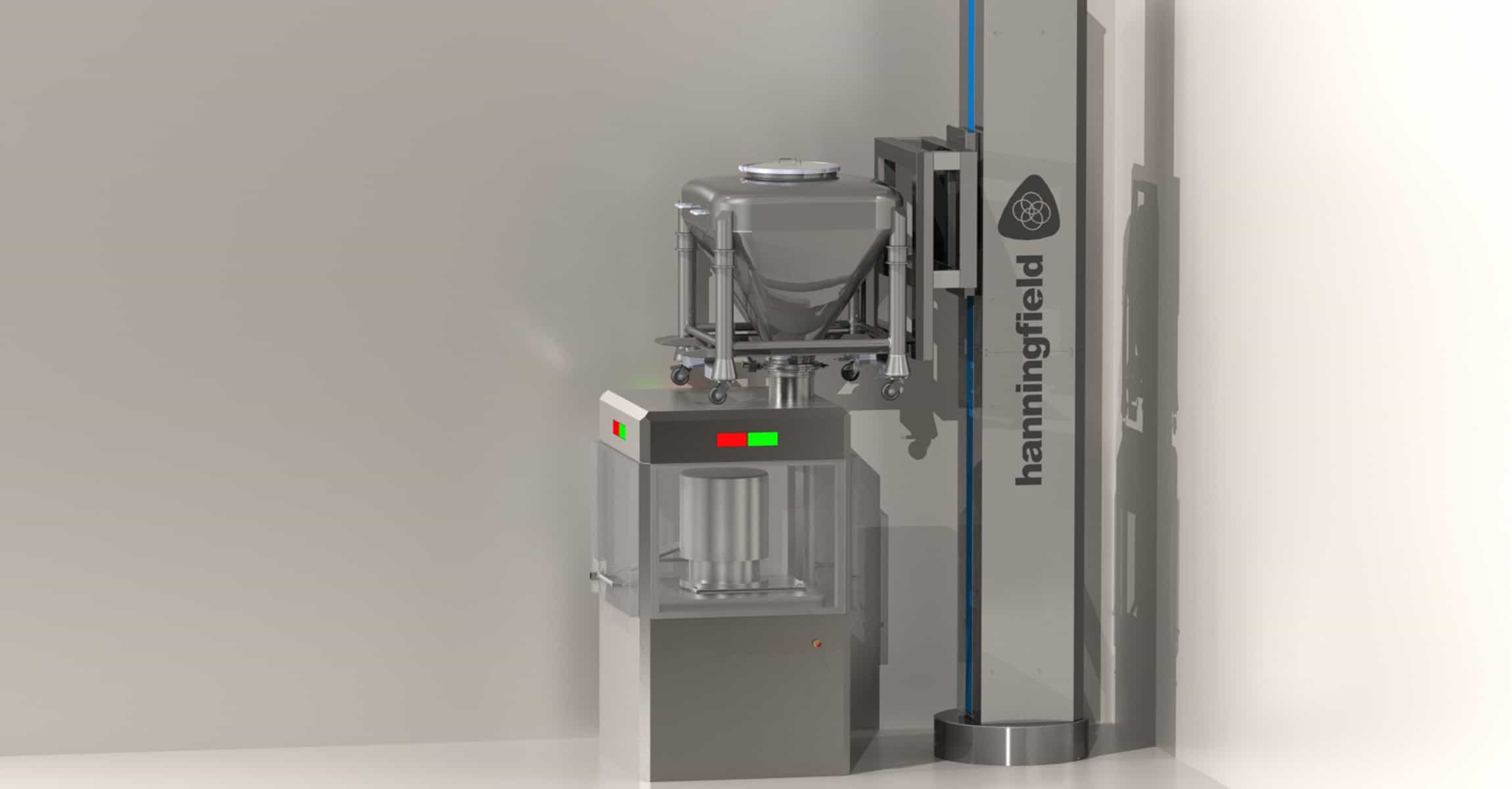

Lifting an IBC above a Tablet Press

The Uni-Hoist HES can be used to raise and dock IBCs above a process machine for discharging powder directly into the loading hopper.

Further examples of how our equipment can be integrated are shown below >>

Get in Touch

If you would like to speak to one of our experts regarding integrating our systems into your process, send us a message using our Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.