Transfer it. Convey it. Transport it. Automate it.

Vacuum conveying is a clean, efficient and environmentally friendly method of transferring powders and granules within a contained system.

Hanningfield supply a range of vacuum conveyor systems (the Uni-Vac series) for the fast and contained transfer of powders, granules, flakes and pellets. These systems are designed with performance and strict hygiene criteria in mind, making them suitable for use in high-integrity applications such as pharmaceutical, food, chemical and nuclear projects.

The Hanningfield Uni-Vac system increases throughput and efficiency, reduces the loss of materials, and minimises the risk of contamination. The Uni-Vac uses negative pressure to transport bulk material in a dust free manner through smooth bore conveying pipe-work. From pick-up to the discharge point, the system is totally enclosed; a major benefit to the environment and process personnel.

How does it work?

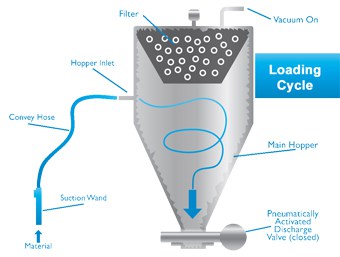

The Loading (Charging) Cycle

Material is sucked into the vacuum hopper using a hand held vacuum wand or feed-bin arrangement. During the loading or ‘convey cycle’ vacuum is drawn on the vacuum hopper lid through a filter, thus drawing the material to be conveyed into the vacuum hopper chamber. Vacuum is present throughout the loading cycle and interrupted only during the unloading cycle. The outlet or ‘discharge-valve’ remains closed during the loading phase.

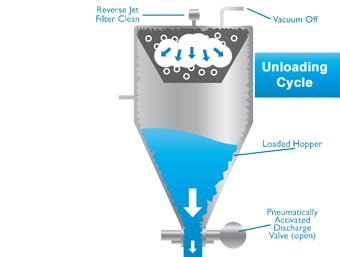

The Unloading (Discharging) Cycle

Once the hopper is full (controlled by timer) vacuum is relieved and the discharge valve at the base of the vacuum hopper opens. Material then falls by gravity to the receiving container situated below. During the unloading of material ‘discharge cycle’ a reverse jet compressed air blast cleans the filter in the lid of the hopper. An option is available to use a bag shaker mechanism in place of the reverse jet air blast. At the end of the discharge cycle the system automatically resets to continue on with the next convey cycle.

Learn more about how our vacuum transfer systems are typically employed to improve your process >>

Find out how our vacuum conveyor systems can be easily disassembled for cleaning >>

Get in Touch

If you would like to speak to one of our experts regarding our Vacuum Conveyor Systems or you would like a quote for one of our products, send us a message using our contact form or Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.