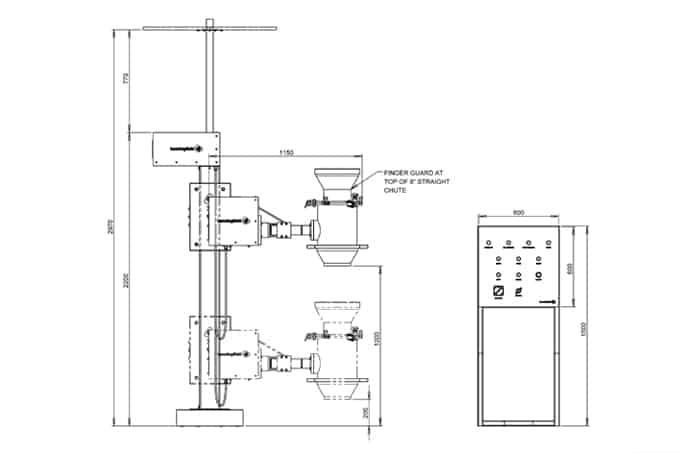

The latest project featured a Uni-Mill M20-U mounted to an electric hoist for simple raise and lower of the machine. The hoist itself features a manual rotating base, allowing the slewing of the load with minimal effort (but with enough resistance to prevent movement during operation). This allows the unit on site to be accurately and repeatably positioned between the inlet and outlet of equipment on site.

Project Images

Project Video

Conical Mill Features and Benefits

Features:

> Stainless steel construction (with 316L contact parts)

> All seals FDA compliant (silicone, PTFE etc.)

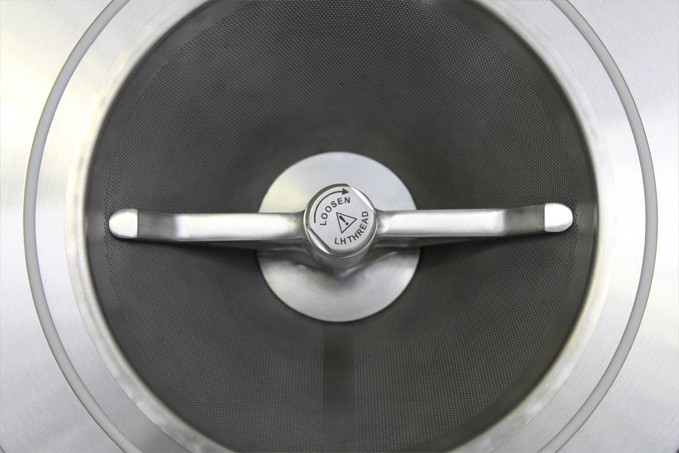

> No metal-to-metal contact

> Easy-clean, GMP design (with optional features such as detachable millhead for autoclave or CIP/WIP)

> ATEX (ex-proof) versions available

Benefits:

> High throughput for maximum productivity

> Inline feed and discharge for higher capacity and ease of system integration (minimal stack-up height and no offset between inlet/outlet)

> Achieve various particle sizes on one machine, simply by changing screen and / or impeller

> Spacerless design with preset optimised ‘gap’ for milling

> Easy to operate

> Low heat, dust and noise generation for improved working environment

> Process scalability from lab to pilot to production

Get in Touch

If you would like to speak to one of our experts regarding our Conical Mills or you would like a quote for one of our products, send us a message using our Contact Form or call us on +44 (0)1702 549 777.

To keep up-to-date with the latest news from Hanningfield you can follow us on LinkedIn.